Matrix™ Tower

For 75% Organic Recovery from Aqueous

Matrix Tower for Removal

of Organic from Aqueous

Standard Features

- Easily recovered organic

- No air introduction

- Reliable performance

- Hydrophobic Matrix plates for coalescing

- No moving parts

- Simple, safe operation

Matrix Tower For Organic Coalescing

The SpinTek Matrix™ Tower is specifically designed to provide

excellent organic recovery of up to 75% from the electrolyte or

raffinate stream of solvent extraction plants without air injection. The

recovery of organic improves the operating efficiency of the plant and

greatly reduces the backwash frequency of the dual media filters prior

to electro winning.

The Matrix Towers are free standing, self-contained filtration units

available in a variety of standard sizes with individual flow rates of

up to 2,000 gpm (454 m3/hr) with multiple units accommodating higher

flow rates. All vessels, packing and organic sensing probes are provided

for a completely automatic system.

How The Filtration System Operates

The Matrix Tower has no moving parts, unlike other filtration systems.

Aqueous enters through the bottom of the Matrix Tower and flows upward

through SpinTek’s hydrophobic non-clogging Matrix media packing. The

Matrix media packing provides a vast surface area for the organic in the

aqueous stream to coalesce or "stick" to and collect.

Additional organic will "stick" to the organic already on the

plates to form larger droplets that will then break free and begin to

float. These large organic droplets formed in the Matrix Tower are

released from the packing to flow along with the aqueous moving upward

through the packing.

Once the aqueous flow passes through the media packing it takes a

reverse turn and flows down through the outer shell of the Matrix Tower.

The lighter coalesced organic will continue in a upwardly direction and

collect in the top of the tower. Here the concentrated organic is

collected and automatically discharged from the tower for reuse in the

plant, completing the filtration cycle.

Stable Trouble Free Operation

The Matrix Tower works well regardless of the level of incoming organic

in the aqueous stream. Other filtration systems which rely on air

flotation must be constantly adjusted to maintain satisfactory removal

efficiencies. Air flotation of organic also causes potential personnel

and environmental hazards by gassing off diluent into the air. By

contrast, the Matrix Tower is a completely sealed filtration system.

This safety measure assures the prevention of hydrocarbons escaping into

the atmosphere.

Matrix Tower for Removal

of Organic from Aqueous

- Easily recovered organic

- No air introduction

- Reliable performance

- Hydrophobic Matrix plates for coalescing

- No moving parts

- Simple, safe operation

Matrix Tower For Organic Coalescing

The SpinTek Matrix™ Tower is specifically designed to provide

excellent organic recovery of up to 75% from the electrolyte or

raffinate stream of solvent extraction plants without air injection. The

recovery of organic improves the operating efficiency of the plant and

greatly reduces the backwash frequency of the dual media filters prior

to electro winning.

The Matrix Towers are free standing, self-contained filtration units

available in a variety of standard sizes with individual flow rates of

up to 2,000 gpm (454 m3/hr) with multiple units accommodating higher

flow rates. All vessels, packing and organic sensing probes are provided

for a completely automatic system.

How The Filtration System Operates

The Matrix Tower has no moving parts, unlike other filtration systems.

Aqueous enters through the bottom of the Matrix Tower and flows upward

through SpinTek’s hydrophobic non-clogging Matrix media packing. The

Matrix media packing provides a vast surface area for the organic in the

aqueous stream to coalesce or "stick" to and collect.

Additional organic will "stick" to the organic already on the

plates to form larger droplets that will then break free and begin to

float. These large organic droplets formed in the Matrix Tower are

released from the packing to flow along with the aqueous moving upward

through the packing.

Once the aqueous flow passes through the media packing it takes a

reverse turn and flows down through the outer shell of the Matrix Tower.

The lighter coalesced organic will continue in a upwardly direction and

collect in the top of the tower. Here the concentrated organic is

collected and automatically discharged from the tower for reuse in the

plant, completing the filtration cycle.

Stable Trouble Free Operation

The Matrix Tower works well regardless of the level of incoming organic

in the aqueous stream. Other filtration systems which rely on air

flotation must be constantly adjusted to maintain satisfactory removal

efficiencies. Air flotation of organic also causes potential personnel

and environmental hazards by gassing off diluent into the air. By

contrast, the Matrix Tower is a completely sealed filtration system.

This safety measure assures the prevention of hydrocarbons escaping into

the atmosphere.

Once the aqueous flow passes through the media packing it takes a reverse turn and flows down through the outer shell of the Matrix Tower. The lighter coalesced organic will continue in a upwardly direction and collect in the top of the tower. Here the concentrated organic is collected and automatically discharged from the tower for reuse in the plant, completing the filtration cycle.

Stable Trouble Free Operation

The Matrix Tower works well regardless of the level of incoming organic

in the aqueous stream. Other filtration systems which rely on air

flotation must be constantly adjusted to maintain satisfactory removal

efficiencies. Air flotation of organic also causes potential personnel

and environmental hazards by gassing off diluent into the air. By

contrast, the Matrix Tower is a completely sealed filtration system.

This safety measure assures the prevention of hydrocarbons escaping into

the atmosphere.

| Model Number | Service Flow Rate | Pipe Size | Height | Width | Depth |

|---|---|---|---|---|---|

| MT-900 | 1 m3/hr | 2″ | 3.0 m | 0.2 m | 0.2 m |

| MT-940 | 2 m3/hr | 2″ | 3.0 m | 0.3 m | 0.3 m |

| MT-960 | 5 m3/hr | 2″ | 3.0 m | 0.5 m | 0.5 m |

| MT-980 | 9 m3/hr | 2″ | 3.0 m | 0.6 m | 0.6 m |

| MT-990 | 20 m3/hr | 3″ | 3.0 m | 0.9 m | 0.9 m |

| MT-1000 | 36 m3/hr | 4″ | 3.0 m | 1.2 m | 1.2 m |

| MT-1010 | 56 m3/hr | 4″ | 3.4 m | 1.5 m | 1.5 m |

| MT-1020 | 80 m3/hr | 6″ | 3.4 m | 1.8 m | 1.8 m |

| MT-1030 | 109 m3/hr | 6″ | 3.7 m | 2.1 m | 2.1 m |

| MT-1040 | 143 m3/hr | 8″ | 3.7 m | 2.4 m | 2.4 m |

| MT-1050 | 181 m3/hr | 8″ | 4.0 m | 2.7 m | 2.7 m |

| MT-1060 | 223 m3/hr | 8″ | 4.0 m | 3.0 m | 3.0 m |

| MT-1070 | 270 m3/hr | 10″ | 4.3 m | 3.4 m | 3.4 m |

| MT-1080 | 321 m3/hr | 10″ | 4.3 m | 3.7 m | 3.7 m |

| MT-1090 | 377 m3/hr | 12″ | 4.3 m | 4.0 m | 4.0 m |

| MT-1100 | 437 m3/hr | 12″ | 4.6 m | 4.3 m | 4.3 m |

___________________________________________________________________________________

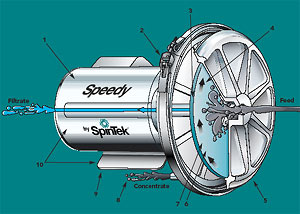

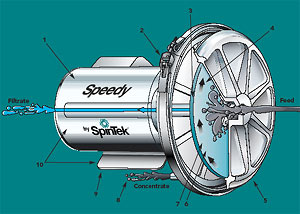

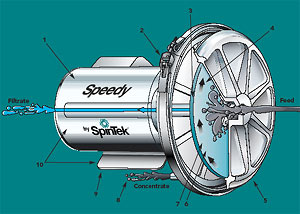

Speedy™ by SpinTek

Rotating Ceramic Ultrafilter

Foul-resistant, high-shear filtration system for parts bath

solutions

High Productivity

Speedy™ by SpinTek solves filtration problems associated with

high temperature, highly alkaline process streams and metal

working fluids. This compact, high shear Rotating Ceramic

Ultrafilter (RCU) significantly extends bath life in a typical

metalworking or parts shop. Speedy features a rapidly spinning

eleven-inch ceramic membrane disk to generate shear that is

orders of magnitude greater than conventional UF systems. This

powerful rotational shear prevents fouling and provides high,

very stable system throughput. As a result, Speedy promotes

longer bath life by effectively maintaining viable bath

chemistries.

Speedy™ by SpinTek solves filtration problems associated with

high temperature, highly alkaline process streams and metal

working fluids. This compact, high shear Rotating Ceramic

Ultrafilter (RCU) significantly extends bath life in a typical

metalworking or parts shop. Speedy features a rapidly spinning

eleven-inch ceramic membrane disk to generate shear that is

orders of magnitude greater than conventional UF systems. This

powerful rotational shear prevents fouling and provides high,

very stable system throughput. As a result, Speedy promotes

longer bath life by effectively maintaining viable bath

chemistries.

Low Maintenance

SpinTek’s high-shear, Rotating Ceramic Ultrafilter is proven

superior in treating highly viscous waste streams that were

previously considered untreatable. Its ceramic membrane is

easily removed for quick cleaning and inspection — simply

remove a few bolts and sponge off the ceramic membrane disk.

The result is dramatically reduced downtime and maintenance

costs, savings on bath solutions, and cleaner parts. Speedy

requires minimal operator assistance and the small footprint

saves space in facilities where floor space is at a premium.

SpinTek’s high-shear, Rotating Ceramic Ultrafilter is proven

superior in treating highly viscous waste streams that were

previously considered untreatable. Its ceramic membrane is

easily removed for quick cleaning and inspection — simply

remove a few bolts and sponge off the ceramic membrane disk.

The result is dramatically reduced downtime and maintenance

costs, savings on bath solutions, and cleaner parts. Speedy

requires minimal operator assistance and the small footprint

saves space in facilities where floor space is at a premium.

Key Benefits

- Improves performance, significantly decreases downtime,

and extends bath life

- Quick release clamp facilitates fast, easy opening of unit

for membrane cleaning and maintenance

- Single disk ceramic membrane withstands heat, high pH

- Powerful rotational shear prevents fouling and provides

high, very stable system throughput

- Available in multiple disk configurations

- Virtually foul-resistant with especially oily or sludgy

streams

- Spinning eleven-inch ceramic disk generates shear that is

orders of magnitude greater than conventional UF systems

- Concentrates waste and process streams previously

considered untreatable

- Costs up to 75% less than competitive ultrafiltration

technologies

- Small footprint eliminates floor space cramping

ST-II Concept

Speedy’s innovative design is based on

SpinTek’s patented ST-II Rotating Ceramic Ultrafilter (RCU)

technology.

Highly Effective Membranes

SpinTek has spent nearly three decades in the research and

development of its ceramic membranes and centrifugal systems.

Formed from a fine, ceramic nanopowder, the SpinTek membranes

better resist fouling from oily and sludgy materials. Combined

with high shear that is orders of magnitude greater than

conventional UF systems, Speedy’s ceramic membranes allow the

system to process a wide variety of viscous solutions containing

moderate to high solids.

Choose Your Configuration

Speedy is available in a single disk configuration that is

especially well-suited for operations with parts baths of 350

gallons or less. For larger volumes, Speedy is available in

multiple disk configurations. The five-disk Speedy unit can

process up to 1,500 gallons per day. Speedy’s low cost

combined with savings from reduced maintenance and downtime

brings a quick return on investment.

Specifications

Gallons Per Day - 300 per single disk (approximate)

Types of Solutions - Oily waste, aqueous cleaner, liquid/solid

separation

Concentration Percentage - Up to 60%

Size - Speedy - 18″L x 12″W x 12″H

Complete System - 3.0′L x 3.5′W x 5.0′H

Weight - Base Unit 70lbs, Complete System 175lbs.

Footprint - 18″ x 18″ (Base)

3.5′ x 3.5′ (Complete System)

Configurations Available

Single Disk (RCU) 300 gal/day (approximate)

5 Disk (RCU) up to 1,500 gal/day (approximate)

10 Disk (RCU) 3,000 gal/day (approximate)

*Complete system includes a single disk unit with 11 inch

membrane, process tank with integral pretreatment, transfer and

circulation pump, bag filter and instrumentation and control

panel.

Speedy Process and Instrumentation

Low Maintenance

SpinTek’s high-shear, Rotating Ceramic Ultrafilter is proven

superior in treating highly viscous waste streams that were

previously considered untreatable. Its ceramic membrane is

easily removed for quick cleaning and inspection — simply

remove a few bolts and sponge off the ceramic membrane disk.

The result is dramatically reduced downtime and maintenance

costs, savings on bath solutions, and cleaner parts. Speedy

requires minimal operator assistance and the small footprint

saves space in facilities where floor space is at a premium.

SpinTek’s high-shear, Rotating Ceramic Ultrafilter is proven

superior in treating highly viscous waste streams that were

previously considered untreatable. Its ceramic membrane is

easily removed for quick cleaning and inspection — simply

remove a few bolts and sponge off the ceramic membrane disk.

The result is dramatically reduced downtime and maintenance

costs, savings on bath solutions, and cleaner parts. Speedy

requires minimal operator assistance and the small footprint

saves space in facilities where floor space is at a premium.

Key Benefits

- Improves performance, significantly decreases downtime,

and extends bath life

- Quick release clamp facilitates fast, easy opening of unit

for membrane cleaning and maintenance

- Single disk ceramic membrane withstands heat, high pH

- Powerful rotational shear prevents fouling and provides

high, very stable system throughput

- Available in multiple disk configurations

- Virtually foul-resistant with especially oily or sludgy

streams

- Spinning eleven-inch ceramic disk generates shear that is

orders of magnitude greater than conventional UF systems

- Concentrates waste and process streams previously

considered untreatable

- Costs up to 75% less than competitive ultrafiltration

technologies

- Small footprint eliminates floor space cramping

ST-II Concept

Speedy’s innovative design is based on

SpinTek’s patented ST-II Rotating Ceramic Ultrafilter (RCU)

technology.

Highly Effective Membranes

SpinTek has spent nearly three decades in the research and

development of its ceramic membranes and centrifugal systems.

Formed from a fine, ceramic nanopowder, the SpinTek membranes

better resist fouling from oily and sludgy materials. Combined

with high shear that is orders of magnitude greater than

conventional UF systems, Speedy’s ceramic membranes allow the

system to process a wide variety of viscous solutions containing

moderate to high solids.

Choose Your Configuration

Speedy is available in a single disk configuration that is

especially well-suited for operations with parts baths of 350

gallons or less. For larger volumes, Speedy is available in

multiple disk configurations. The five-disk Speedy unit can

process up to 1,500 gallons per day. Speedy’s low cost

combined with savings from reduced maintenance and downtime

brings a quick return on investment.

Specifications

Gallons Per Day - 300 per single disk (approximate)

Types of Solutions - Oily waste, aqueous cleaner, liquid/solid

separation

Concentration Percentage - Up to 60%

Size - Speedy - 18″L x 12″W x 12″H

Complete System - 3.0′L x 3.5′W x 5.0′H

Weight - Base Unit 70lbs, Complete System 175lbs.

Footprint - 18″ x 18″ (Base)

3.5′ x 3.5′ (Complete System)

Configurations Available

Single Disk (RCU) 300 gal/day (approximate)

5 Disk (RCU) up to 1,500 gal/day (approximate)

10 Disk (RCU) 3,000 gal/day (approximate)

*Complete system includes a single disk unit with 11 inch

membrane, process tank with integral pretreatment, transfer and

circulation pump, bag filter and instrumentation and control

panel.

Speedy Process and Instrumentation

- Improves performance, significantly decreases downtime, and extends bath life

- Quick release clamp facilitates fast, easy opening of unit for membrane cleaning and maintenance

- Single disk ceramic membrane withstands heat, high pH

- Powerful rotational shear prevents fouling and provides high, very stable system throughput

- Available in multiple disk configurations

- Virtually foul-resistant with especially oily or sludgy streams

- Spinning eleven-inch ceramic disk generates shear that is orders of magnitude greater than conventional UF systems

- Concentrates waste and process streams previously considered untreatable

- Costs up to 75% less than competitive ultrafiltration technologies

- Small footprint eliminates floor space cramping

Speedy’s innovative design is based on SpinTek’s patented ST-II Rotating Ceramic Ultrafilter (RCU) technology.

Highly Effective Membranes

SpinTek has spent nearly three decades in the research and

development of its ceramic membranes and centrifugal systems.

Formed from a fine, ceramic nanopowder, the SpinTek membranes

better resist fouling from oily and sludgy materials. Combined

with high shear that is orders of magnitude greater than

conventional UF systems, Speedy’s ceramic membranes allow the

system to process a wide variety of viscous solutions containing

moderate to high solids.

Choose Your Configuration

Speedy is available in a single disk configuration that is

especially well-suited for operations with parts baths of 350

gallons or less. For larger volumes, Speedy is available in

multiple disk configurations. The five-disk Speedy unit can

process up to 1,500 gallons per day. Speedy’s low cost

combined with savings from reduced maintenance and downtime

brings a quick return on investment.

Specifications

Gallons Per Day - 300 per single disk (approximate)

Types of Solutions - Oily waste, aqueous cleaner, liquid/solid

separation

Concentration Percentage - Up to 60%

Size - Speedy - 18″L x 12″W x 12″H

Complete System - 3.0′L x 3.5′W x 5.0′H

Weight - Base Unit 70lbs, Complete System 175lbs.

Footprint - 18″ x 18″ (Base)

3.5′ x 3.5′ (Complete System)

Configurations Available

Single Disk (RCU) 300 gal/day (approximate)

5 Disk (RCU) up to 1,500 gal/day (approximate)

10 Disk (RCU) 3,000 gal/day (approximate)

*Complete system includes a single disk unit with 11 inch

membrane, process tank with integral pretreatment, transfer and

circulation pump, bag filter and instrumentation and control

panel.

Speedy Process and Instrumentation

Specifications

Gallons Per Day - 300 per single disk (approximate)

Types of Solutions - Oily waste, aqueous cleaner, liquid/solid

separation

Concentration Percentage - Up to 60%

Size - Speedy - 18″L x 12″W x 12″H

Complete System - 3.0′L x 3.5′W x 5.0′H

Weight - Base Unit 70lbs, Complete System 175lbs.

Footprint - 18″ x 18″ (Base)

3.5′ x 3.5′ (Complete System)

Configurations Available

Single Disk (RCU) 300 gal/day (approximate)

5 Disk (RCU) up to 1,500 gal/day (approximate)

10 Disk (RCU) 3,000 gal/day (approximate)

*Complete system includes a single disk unit with 11 inch

membrane, process tank with integral pretreatment, transfer and

circulation pump, bag filter and instrumentation and control

panel.

Speedy Process and Instrumentation

5 Disk (RCU) up to 1,500 gal/day (approximate)

10 Disk (RCU) 3,000 gal/day (approximate)

*Complete system includes a single disk unit with 11 inch membrane, process tank with integral pretreatment, transfer and circulation pump, bag filter and instrumentation and control panel.

Speedy Process and Instrumentation

The SpinTek SX filters are specifically designed to provide excellent

organic removal and filtered electrolyte for the solvent extraction market.

The filters are ruggedly designed and built to operate in the difficult

environments of solvent extraction plants.

The SpinTek SX filters are specifically designed to provide excellent

organic removal and filtered electrolyte for the solvent extraction market.

The filters are ruggedly designed and built to operate in the difficult

environments of solvent extraction plants.